What We Do

Our Assets

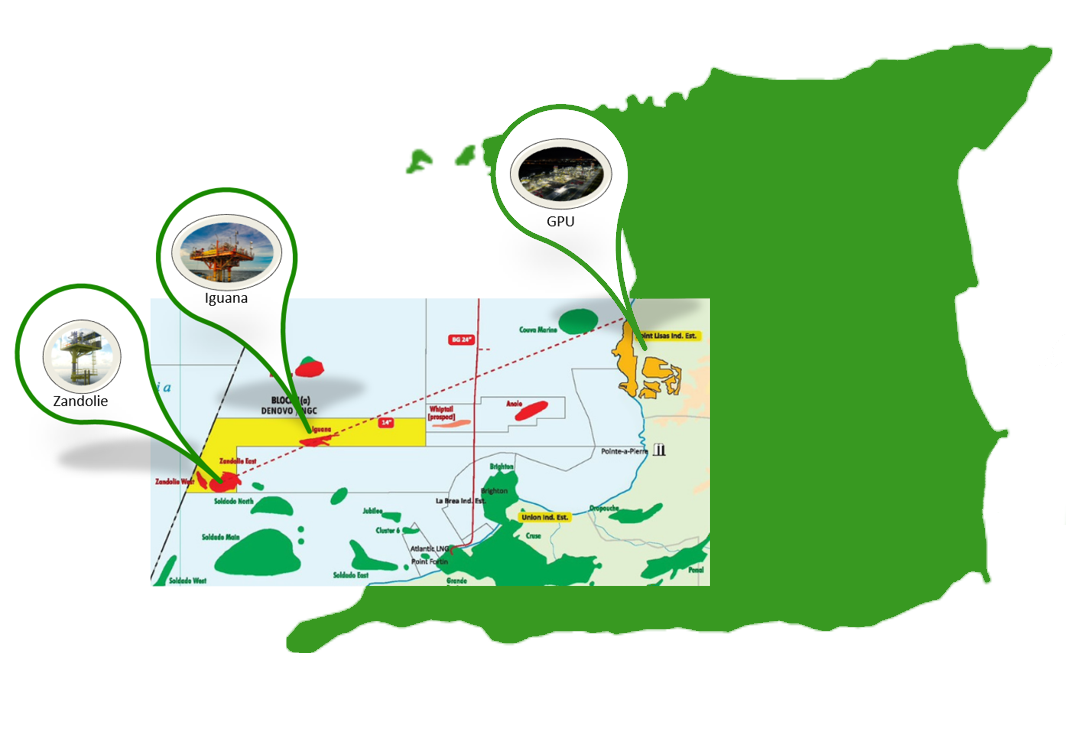

Block 1 (a) is located on the west coast of Trinidad approximately 45 kms offshore from the Point Lisas Industrial Estate.

Block 1(a) contains two natural gas fields: Iguana and Zandolie.

ZANDOLIE FIELD DEVELOPMENT

The Zandolie field is DeNovo’s second field development project. First discovered in 1962 by Trinmar Limited and later appraised by Petro Canada in 2008, Zandolie represents DeNovo’s commitment to increasing natural gas supply to the petrochemical sector in Trinidad and Tobago. Gas production from Zandolie is able to backfill Iguana Field production and extend the life of Block 1 (a).

-

Key Features include:

- Zero LTIs.

- 100% ‘Green’ platform powered by a combination of wind and solar energy.

- Maximisation of local content.

- Platform built in country and drilling conducted by a local jack up rig.

- Winner of Best Decarbonisation Project 2022 from the Energy Chamber of Trinidad and Tobago.

The Zandolie field is DeNovo’s second field development project. First discovered in 1962 by Trinmar Limited and later appraised by Petro Canada in 2008, Zandolie represents DeNovo’s commitment to increasing natural gas supply to the petrochemical sector in Trinidad and Tobago. Gas production from Zandolie is able to backfill Iguana Field production and extend the life of Block 1 (a).

-

Key Features include:

- Zero LTIs.

- 100% ‘Green’ platform powered by a combination of wind and solar energy.

- Maximisation of local content.

- Platform built in country and drilling conducted by a local jack up rig.

- Winner of Best Decarbonisation Project 2022 from the Energy Chamber of Trinidad and Tobago.

DENOVO IGUANA GAS DEVELOPMENT

The Iguana field was first discovered in 1982. It remained undeveloped for over thirty-four (34) years. It was discovered by Petro- Canada, then sold to Centrica before being acquired by DeNovo in 2016.

Key Features:

-

Fast-tracked development of Iguana field within 33 months:

- Zero LTI’s

- c. USD 250 MM investment

- 73% local content

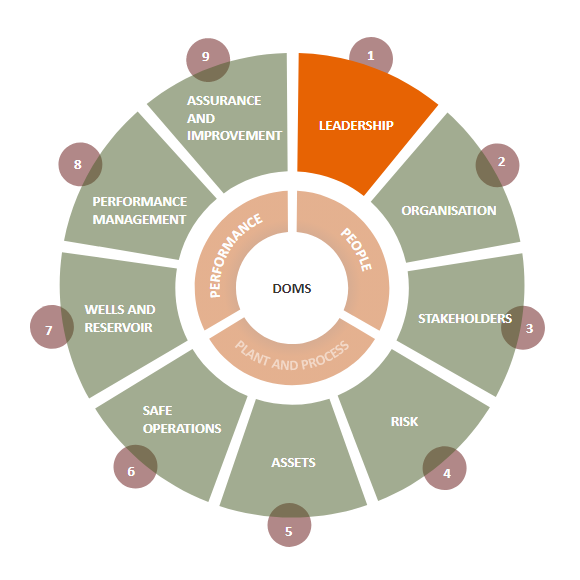

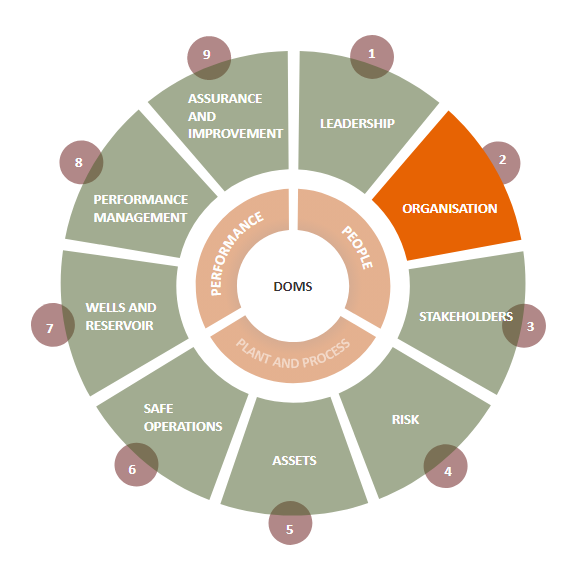

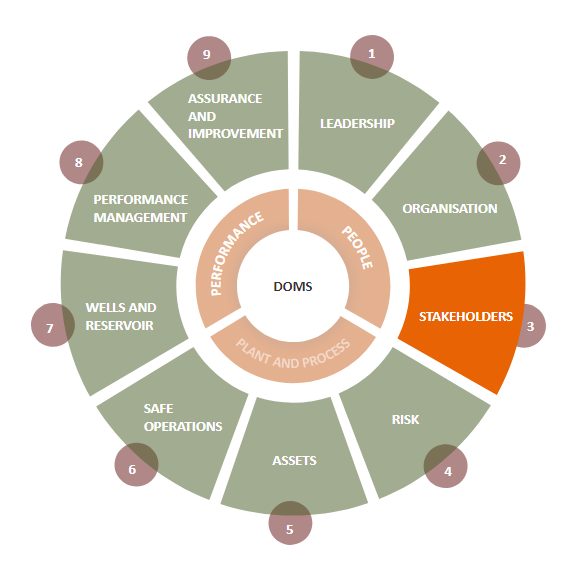

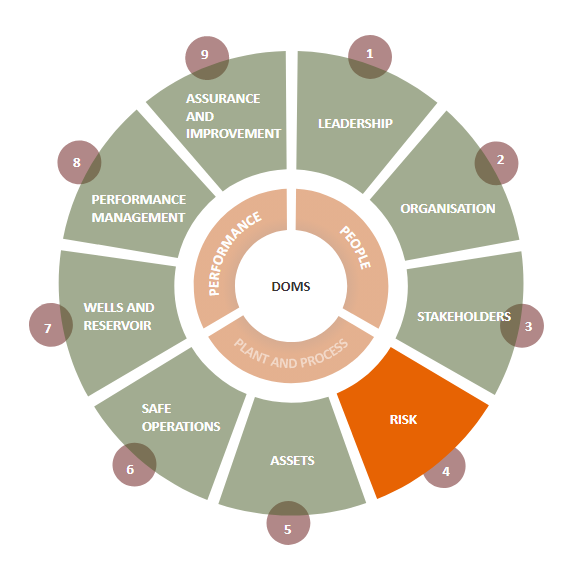

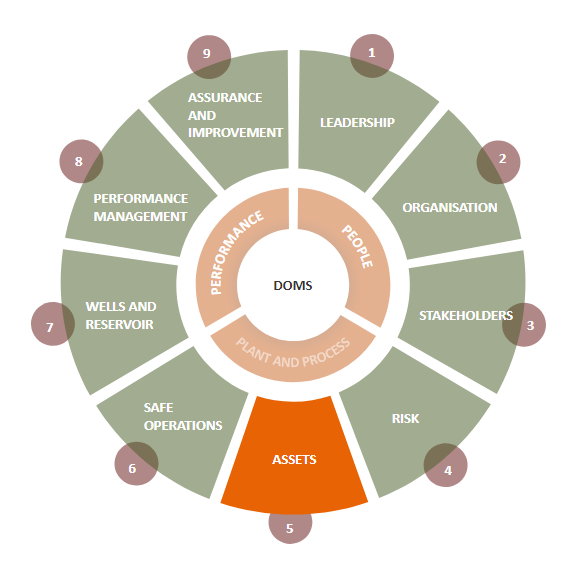

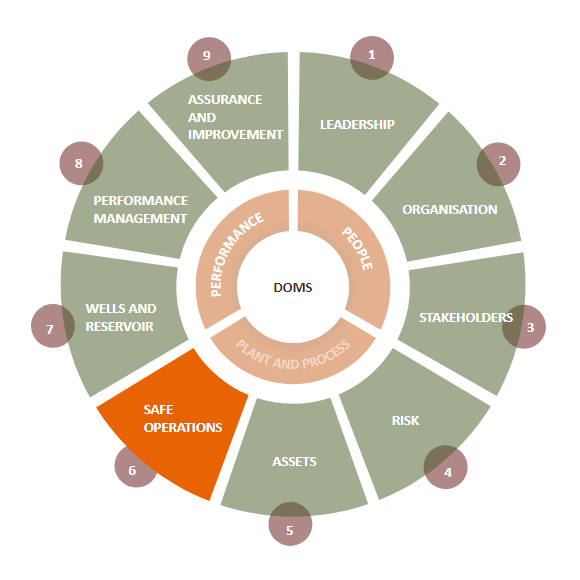

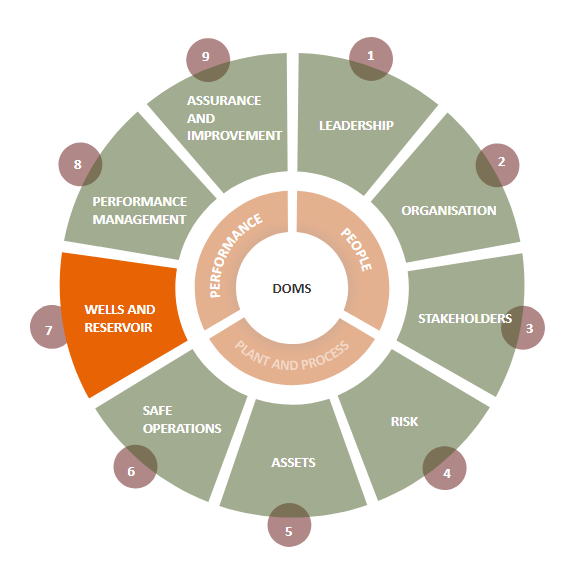

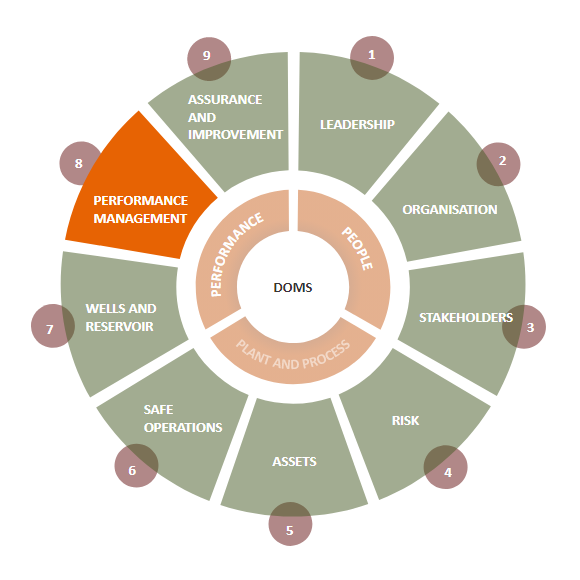

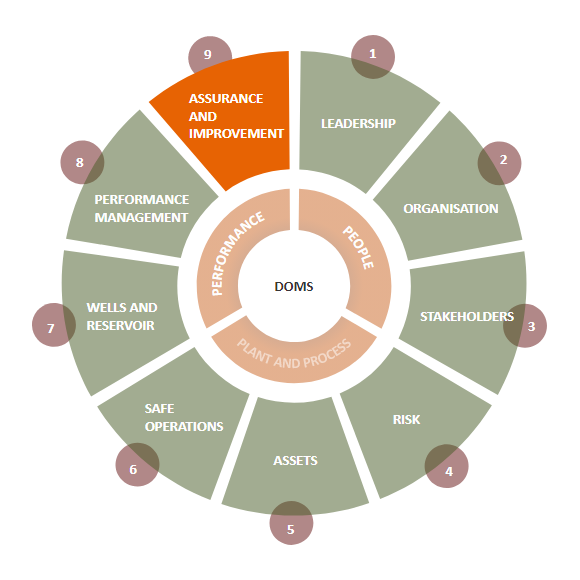

Operating Management System

The DeNovo Operating Management System (DOMS) is fully integrated as a central repository for all standards, practices and procedures that reduces operating risk and maximises efficiency throughout the organisation. The common systems and processes facilitate built-in cross functional capability, and enable quick decision making using easily accessible information on operations. Performance management, measurement and reporting are all defined in DOMS.

Leadership

Our operating leaders ensure that operating activities are built into the business strategy, implemented and assured on the ground, and supported by consistent leadership behaviour that drives a culture of safe, reliable, efficient and ethical operations.

Organisation

The DeNovo organisation is designed to ensure that it is fit-for-purpose, staffed with the right people who are competent to deliver safely, reliably and efficiently in accordance with DOMS.

Stakeholders

DeNovo acts responsibly to ensure that the organisation and its service providers understand and are held accountable to legal and regulatory requirements and the DeNovo Code of Conduct. We engage proactively with stakeholders and partners to address issues and realise mutually beneficial opportunities that may emerge.

Risk

DeNovo has clear, approved and documented processes and systems to manage operating risks. People at all levels of the organisation understand and use these to prevent accidents and harm to people, to mitigate environmental impact, maintain appropriate security levels and efficiently deliver business goals.

Assets

Our plants, facilities, assets and floating systems are fit for purpose throughout the life cycle of operations.

Safe Operations

Provide a safe location to work. Prevent injuries, illness, incidents that can result in injuries, fatalities, environmental impact or loss of reputation. It is essential that activities and associated risk controls are executed consistently with discipline by authorised and competent persons, as defined in the Policies, Standards and Procedures. Each step of the execution of activities should lead to the desired result and intervention should happen in a timely manner when required.

Wells and Reservoirs

We operate our reservoirs and wells to assure efficient delivery of the reservoir depletion plan over the reservoir life cycle. Our well management operations focus on assuring well integrity to maximise efficient recovery of reservoir potential while reliably delivering daily contracted quantities and maintaining an environmentally safe well operating envelope over the lifecycle of the wells.

Performance Management

DeNovo manages the performance improvement cycle from strategy to execution to deliver competitive performance. The full performance improvement cycle includes risk assessment /prioritisation, planning/control, implementation/operation, measurement/evaluation/corrective action to management review and improvement action.

Assurance and Management

DeNovo performs assessments and audits of operating performance and management processes to assure compliance with legal and DeNovo Requirements, and drive risk reduction and performance improvement.

Leadership

Our operating leaders ensure that operating activities are built into the business strategy, implemented and assured on the ground, and supported by consistent leadership behaviour that drives a culture of safe, reliable, efficient and ethical operations.

Organisation

The DeNovo organisation is designed to ensure that it is fit-for-purpose, staffed with the right people who are competent to deliver safely, reliably and efficiently in accordance with DOMS.

Stakeholders

DeNovo acts responsibly to ensure that the organisation and its service providers understand and are held accountable to legal and regulatory requirements and the DeNovo Code of Conduct. We engage proactively with stakeholders and partners to address issues and realise mutually beneficial opportunities that may emerge.

Risk

DeNovo has clear, approved and documented processes and systems to manage operating risks. People at all levels of the organisation understand and use these to prevent accidents and harm to people, to mitigate environmental impact, maintain appropriate security levels and efficiently deliver business goals.

Assets

Our plants, facilities, assets and floating systems are fit for purpose throughout the life cycle of operations.

Safe Operations

Provide a safe location to work. Prevent injuries, illness, incidents that can result in injuries, fatalities, environmental impact or loss of reputation. It is essential that activities and associated risk controls are executed consistently with discipline by authorised and competent persons, as defined in the Policies, Standards and Procedures. Each step of the execution of activities should lead to the desired result and intervention should happen in a timely manner when required.

Wells and Reservoir

We operate our reservoirs and wells to assure efficient delivery of the reservoir depletion plan over the reservoir life cycle. Our well management operations focus on assuring well integrity to maximise efficient recovery of reservoir potential while reliably delivering daily contracted quantities and maintaining an environmentally safe well operating envelope over the lifecycle of the wells.

Performance Management

DeNovo manages the performance improvement cycle from strategy to execution to deliver competitive performance. The full performance improvement cycle includes risk assessment /prioritisation, planning/control, implementation/operation, measurement/evaluation/corrective action to management review and improvement action.

Assurance and Improvement

DeNovo performs assessments and audits of operating performance and management processes to assure compliance with legal and DeNovo Requirements, and drive risk reduction and performance improvement.

Integrity Compliance Programme

DeNovo’s Integrity Compliance Programme

DeNovo’s Contracts & Procurement Policies and Procedure

DeNovo’s Counter-Corruption Policy

DeNovo’s Environmental, Social and Governance (ESG) Policy

DeNovo’s Internal Control Foundation

DeNovo’s Operations Management System (DOMS)